Quality Assurance

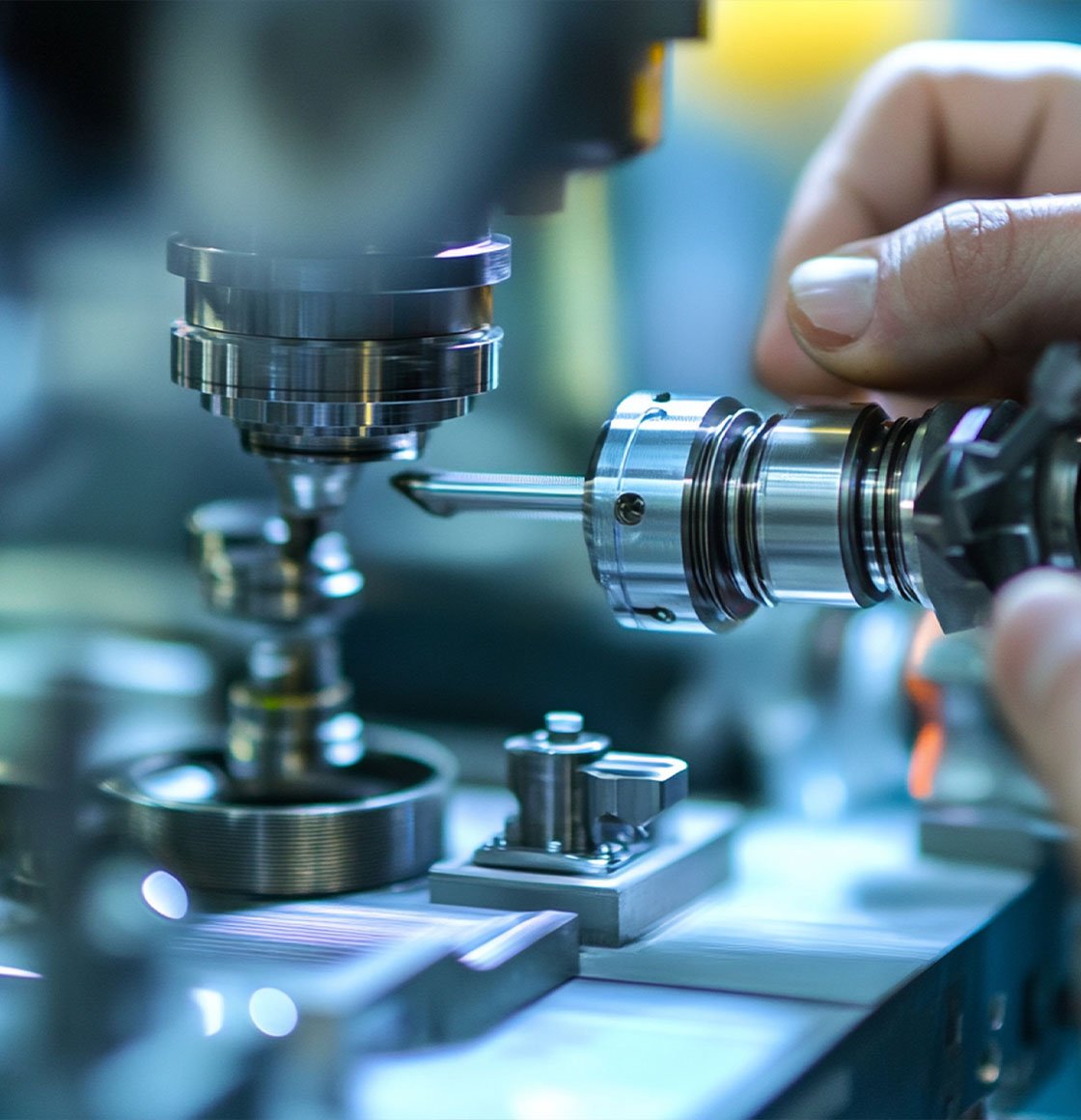

Delivering Superior Quality with Precision and Consistency

At Conex Aluminium Components, quality is not just a goal but a core value embedded in every aspect of our operations. We adhere to the highest standards of quality control, ensuring precision and excellence in every product we manufacture. From raw material selection to rigorous in-process checks and final inspections, our experienced team employs advanced testing equipment and methodologies to ensure that our products meet and exceed global standards. We are ISO 9001:2015 certified, and our commitment to quality extends to maintaining a culture of continuous improvement, innovation, and customer satisfaction. Our focus on quality enables us to deliver reliable, durable, and high-performing components that add value to our clients' businesses.

Quality Testing

Comprehensive Quality Check Processes

Raw Material Testing

Initial inspection of raw materials for composition, hardness, and purity.

01

In-Process Inspection

Continuous monitoring during production to ensure dimensional accuracy and consistency.

02

Final Product Testing

Detailed inspection of finished products, including surface finish and tolerances.

03

Advanced Testing Methods

Spectrometers, hardness testers, and tensile strength testers for quality validation.

04